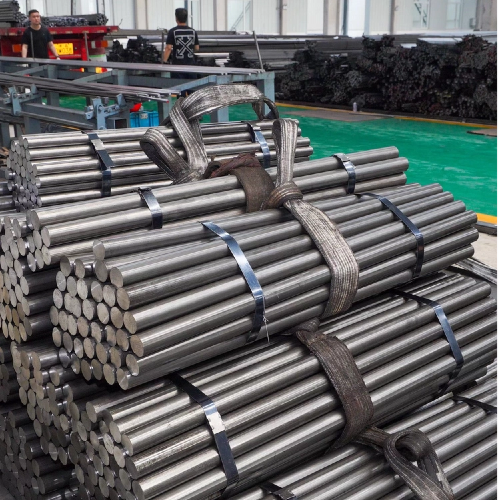

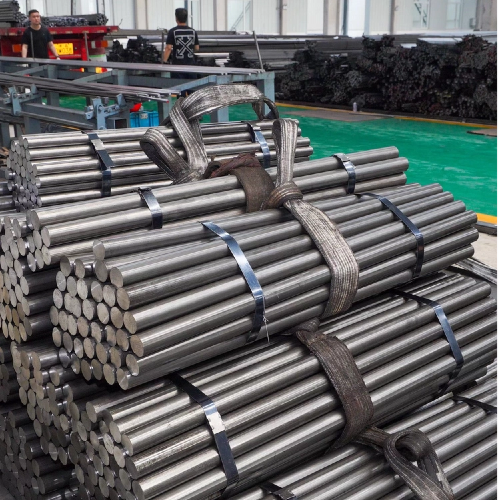

Cold drawn round steel is a versatile and high-performance material widely used across various industries. Its precise dimensional tolerances, superior surface finish, and mechanical properties make it ideal for critical applications in automotive, aerospace, construction, and machinery manufacturing. However, selecting the right cold drawn round steel for your specific project can be challenging due to the various factors that need to be considered.

In this article, we will guide you through the process of selecting the right cold drawn round steel for your project. We will discuss the key factors to consider, including material grade, size, surface finish, and customization options, ensuring you make the most informed decision for your needs.

Introduction to Cold Drawn Round Steel

Cold drawn round steel is produced by pulling steel through a die at room temperature, which increases its strength and precision. The process of cold drawing refines the grain structure, enhancing its mechanical properties such as tensile strength, yield strength, and hardness. Cold drawn steel is known for its superior dimensional accuracy and smooth surface finish, making it a preferred material for applications requiring high strength, durability, and precision.

Choosing the right cold drawn round steel requires an understanding of your project requirements and an in-depth knowledge of the steel's properties. Below, we will explore the various factors that will help you select the best material for your needs.

Understand Your Project Requirements

Application Type

One of the first steps in selecting the right cold drawn round steel is to understand the specific application for which it will be used. Different industries have varying requirements, so it's important to consider the application type before making a decision.

Automotive Manufacturing: For automotive parts such as shafts, suspension components, and axles, cold drawn round steel must meet stringent strength and durability requirements.

Aerospace Engineering: In aerospace, materials like cold drawn round steel are used for components that need to withstand extreme conditions while maintaining a low weight-to-strength ratio.

Construction: Cold drawn round steel is often used in structural components, including reinforcing bars (rebar), where high strength and precision are crucial for safety and stability.

Performance Needs

Once you have determined the application type, you should evaluate the mechanical properties required for the project. Cold drawn round steel can be tailored to meet specific strength, hardness, and elongation requirements based on the project’s needs.

For instance, in heavy-duty machinery, you may need cold drawn round steel with higher tensile strength and fatigue resistance. On the other hand, for precision components, dimensional accuracy and surface finish may be more critical.

Key Factors to Consider When Selecting Cold Drawn Round Steel

Material Grade

The grade of the material plays a crucial role in determining the mechanical properties and performance of the cold drawn round steel. Different grades of steel offer varying levels of strength, hardness, and corrosion resistance.

Steel Grade | Properties | Typical Applications |

Q195 | Low carbon, good weldability, low strength | General fabrication, low-stress parts |

Q235 | Medium carbon, moderate strength | Structural components, construction |

1045 | Medium carbon, high strength, good hardness | Automotive parts, shafts, gears |

40Cr | High carbon, good wear resistance | High-stress components, mechanical parts |

42CrMo | Alloy steel, high toughness and strength | Aerospace, heavy machinery |

When selecting cold drawn round steel, choose a grade that best suits the mechanical demands of your project. For example, 1045 steel is commonly used in the automotive industry for manufacturing shafts and gears, while 42CrMo is preferred for aerospace applications due to its high toughness.

Size and Dimensions

The next step is determining the right size and dimensions for your cold drawn round steel. Cold drawn round steel comes in various diameters, ranging from a few millimeters to several centimeters, and can be customized to meet the specific requirements of your project.

Cold drawn round steel is known for its precise dimensional tolerances, typically ranging from 0.1 to 0.5mm. This is particularly important for applications that require tight tolerances, such as gears, shafts, and fasteners. You should consider both the diameter and length of the steel based on your project’s specifications.

Diameter Range | Tolerance | Applications |

< 10mm | ±0.05mm to ±0.1mm | Small components, fasteners |

10mm to 50mm | ±0.1mm to ±0.2mm | Shafts, bolts, structural parts |

> 50mm | ±0.2mm to ±0.5mm | Heavy-duty components, rods |

The higher the precision required in your project, the tighter the tolerances and finer the finish you will need from your cold drawn round steel.

Surface Finish

Cold drawn round steel is known for its smooth surface finish, which is one of its most significant advantages over hot rolled steel. The cold drawing process helps to eliminate surface imperfections, such as scale and rust, resulting in a clean and uniform surface.

For applications where the steel will be exposed to friction or wear, a smooth surface finish is essential to reduce damage and improve performance. Additionally, the smoother surface facilitates easier machining and welding, reducing the overall cost of processing.

Heat Treatment and Hardness

The cold drawing process itself increases the strength and hardness of the steel, but additional heat treatment may be required depending on the project’s demands. Heat treatments like annealing and quenching can further improve the hardness, toughness, and fatigue resistance of cold drawn round steel.

If your project requires a material with enhanced hardness, such as for cutting tools or high-wear components, heat-treated cold drawn round steel is the ideal option. Conversely, if flexibility and toughness are more critical, annealed cold drawn round steel would be the best choice.

Cold Drawn Round Steel Tolerances and Precision

One of the main advantages of cold drawn round steel is its dimensional precision. The cold drawing process offers a level of accuracy that is difficult to achieve with other methods such as hot rolling or forging. Cold drawn round steel typically has a dimensional tolerance range of ±0.1mm to ±0.5mm, depending on the diameter and length.

Importance of Tolerance in Projects

Dimensional accuracy is critical for applications requiring precision fittings, such as automotive and aerospace components. The tight tolerances of cold drawn round steel ensure that parts fit together seamlessly, reducing the need for further machining and improving overall efficiency.

Benefits of Customizing Cold Drawn Round Steel for Specific Projects

Customization Options

Cold drawn round steel can be customized in terms of size, grade, and finish to meet the specific requirements of a project. Customization is particularly important when dealing with unique applications, as it ensures that the material fits perfectly within the design specifications.

Diameter and Length: Custom diameters and lengths can be ordered to match specific requirements, ensuring that the material works seamlessly within the assembly process.

Material Properties: If your project requires a specific strength, hardness, or wear resistance, cold drawn round steel can be customized with different material grades to meet those needs.

Working with Suppliers for Custom Orders

When placing a custom order for cold drawn round steel, it's important to communicate your project requirements clearly to the supplier. This includes specifying the required dimensions, material grade, surface finish, and any heat treatment processes.

Many suppliers offer tailored solutions, working closely with customers to meet exact specifications. They can help you choose the right material and ensure that it is delivered on time, reducing the risk of delays and cost overruns.

Cost Considerations and Budgeting for Cold Drawn Round Steel

Factors Affecting Cost

The cost of cold drawn round steel depends on several factors, including material grade, size, and customization requirements. Generally, the more precise the steel's dimensions and the higher the strength required, the more expensive the material will be.

Material Grade: Higher-grade materials, such as alloy steels, tend to be more expensive due to their enhanced properties.

Customization: Custom sizes and finishes can increase the cost of cold drawn round steel.

Order Volume: Ordering in bulk may reduce the per-unit cost of cold drawn round steel.

Balancing Quality and Budget

While quality is essential, it is also important to find a balance between cost-effectiveness and performance. By choosing the right material grade and customizing the steel only as necessary, you can optimize the cost without sacrificing quality or performance.

Quality Assurance and Certifications

Quality Standards to Look For

When sourcing cold drawn round steel, ensure that the material meets quality standards and is certified for its intended use. Look for certifications such as ISO 9001 for quality management systems, as well as material certificates that verify the properties of the steel.

Reputable suppliers will provide certificates of compliance that confirm the steel's strength, hardness, and other critical properties, ensuring that it meets the required specifications for your project.

Verifying Product Quality

To ensure that you are receiving high-quality cold drawn round steel, work with trusted suppliers who provide thorough documentation and quality checks. Always verify the material properties before beginning your project to avoid any surprises during manufacturing.

Conclusion

Selecting the right cold drawn round steel for your project is critical to ensuring its performance, durability, and overall success. By carefully evaluating the specific needs of your project—such as material grade, size, surface finish, and heat treatment—you can choose the steel that best fits your requirements. Cold drawn round steel is known for its high dimensional precision, smooth surface finish, and enhanced strength, making it the preferred material across various industries.

At Tianjin Shengxiang Cold Drawn Steel Co., Ltd., we specialize in providing high-quality cold drawn round steel tailored to meet your project’s exact specifications. Our extensive range of grades, sizes, and finishes ensures that you can find the right material for any application, whether it’s for automotive, aerospace, construction, or machinery manufacturing. We are committed to offering reliable, durable steel that meets the highest standards of precision and performance.

Contact us today to discuss your needs, and let us help you select the perfect cold drawn round steel for your project. Our team is ready to provide expert guidance and support throughout the process.

FAQs

Q1: What is the difference between cold drawn round steel and hot rolled steel?

Cold drawn round steel offers much higher dimensional precision and a smoother surface finish compared to hot rolled steel. Cold drawing also enhances strength, making it ideal for applications that require tight tolerances and high performance.

Q2: How do I choose the right material grade for my cold drawn round steel project?

Choose a material grade based on the specific mechanical properties required for your application, such as strength, hardness, and corrosion resistance. For example, 1045 steel is great for automotive applications, while 42CrMo is suitable for aerospace due to its toughness.

Q3: Can cold drawn round steel be customized for specific dimensions?

Yes, cold drawn round steel can be customized in terms of diameter, length, and material grade to meet your project’s specific needs. Customization ensures that the material fits your design requirements perfectly.

Q4: What tolerance levels should I consider when selecting cold drawn round steel for my project?

Cold drawn round steel offers tight tolerances ranging from ±0.1mm to ±0.5mm, which makes it ideal for applications requiring precision, such as gears and shafts.

Q5: How can I ensure the quality of the cold drawn round steel I purchase?

Ensure that the steel meets quality standards such as ISO certifications and ask for material certificates from your supplier. Reputable suppliers will provide documentation confirming the material’s properties to ensure it meets your project specifications.