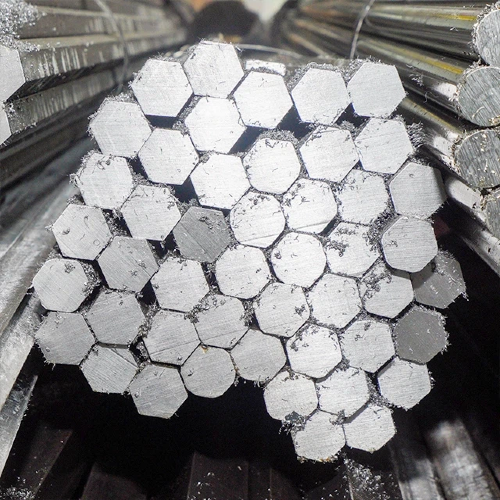

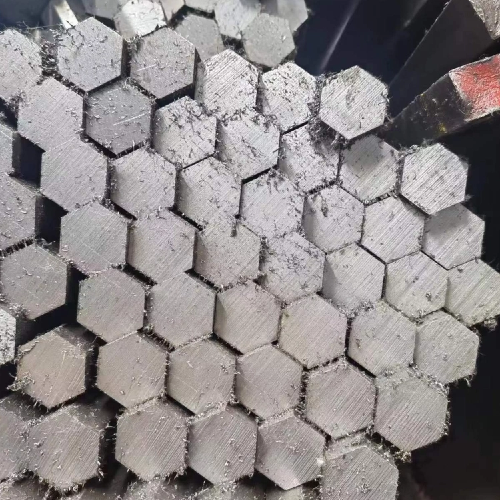

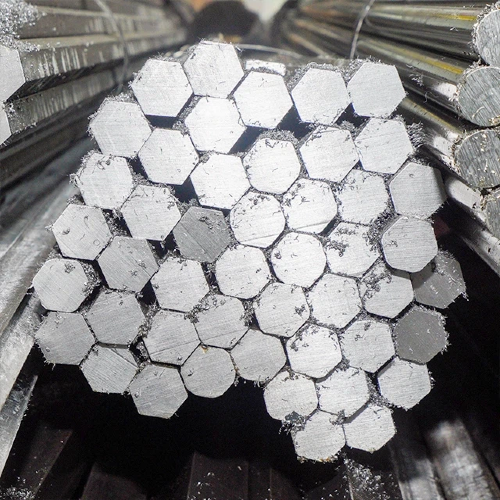

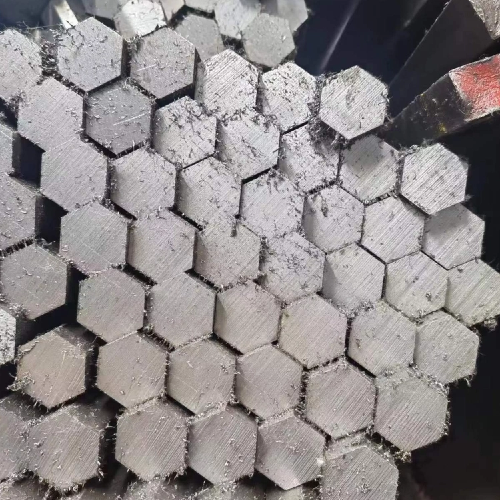

Cold-drawn hexagonal steel is widely recognized for its outstanding mechanical properties, including precision, strength, and durability. Manufactured through the cold-drawing process, this material is ideal for applications that demand high dimensional accuracy, superior surface finish, and increased performance. In this article, we will explore the key benefits of using cold-drawn hexagonal steel and how it can enhance the efficiency, performance, and cost-effectiveness of your project.

What Is Cold-Drawn Hexagonal Steel?

Cold-drawn hexagonal steel is a type of steel bar produced by drawing steel through a die at room temperature. This process refines the steel's shape and mechanical properties, resulting in a material that is stronger, more precise, and smoother than other types of steel. The cold-drawing method involves pulling a hot-rolled hexagonal bar through a die to reduce its size, creating a uniform and consistent product that meets specific application requirements.

Unlike hot-rolled steel, which can have a rough surface finish and wider dimensional tolerances, cold-drawn hexagonal steel provides a clean, smooth finish and tight tolerances, making it ideal for high-precision applications. It is commonly used in industries such as automotive manufacturing, aerospace, and construction, where strength and precision are essential.

Key Benefits of Using Cold-Drawn Hexagonal Steel

High Dimensional Precision

One of the primary advantages of cold-drawn hexagonal steel is its high dimensional precision. The cold-drawing process enables manufacturers to achieve tight tolerances, typically ranging from ±0.05mm to ±0.1mm. This is particularly beneficial for applications requiring exact measurements and where any deviation in size could affect the performance of the final product.

The high precision of cold-drawn hexagonal steel ensures that components fit seamlessly during assembly, reducing the need for additional machining or adjustments. This makes it an excellent choice for industries like automotive manufacturing, where precision is critical for safety and performance.

Diameter Range | Tolerance | Applications |

< 10mm | ±0.05mm to ±0.1mm | Small components, fasteners |

10mm to 50mm | ±0.1mm to ±0.2mm | Shafts, structural parts |

> 50mm | ±0.2mm to ±0.5mm | Heavy-duty components, rods |

Superior Surface Finish

Cold-drawn hexagonal steel also stands out for its superior surface finish. The cold-drawing process eliminates scale, rust, and other imperfections found on hot-rolled steel, resulting in a smooth, clean surface. This smooth finish reduces friction and wear in parts that are subjected to repetitive motion, making it ideal for applications like machinery components, fasteners, and automotive parts.

In addition to functional benefits, a smooth surface finish improves the aesthetic quality of the material, which is particularly important in visible components or parts that require additional surface treatments like plating or coating.

Enhanced Strength and Durability

Cold-drawn hexagonal steel undergoes a significant improvement in strength and durability due to the cold-working process. This process refines the steel's grain structure, increasing its tensile strength, yield strength, and hardness compared to hot-rolled steel. Cold-drawn hexagonal steel is stronger and more resistant to fatigue, making it suitable for high-stress applications where long-term performance and reliability are critical.

The enhanced strength of cold-drawn hexagonal steel reduces the likelihood of deformation, breakage, or failure under pressure. This is especially important in industries like construction and automotive manufacturing, where safety and durability are paramount.

Uniform Mechanical Properties

Cold-drawing ensures uniformity in mechanical properties across the entire length of the steel bar. Unlike some manufacturing processes, which can result in variations in strength, toughness, or hardness, cold-drawn hexagonal steel maintains consistent characteristics throughout. This uniformity is essential in mass production, where each part must meet the same standards for performance and quality.

This consistency in mechanical properties helps reduce the chances of defects or failures, improving the overall quality and reliability of the final product.

Increased Resistance to Fatigue and Wear

Due to the refinement of its microstructure, cold-drawn hexagonal steel exhibits increased resistance to fatigue and wear. This is particularly beneficial in high-stress environments where materials are subjected to repetitive loading and harsh conditions. Components made from cold-drawn hexagonal steel are less likely to crack, deform, or fail under repeated stress.

This feature makes it an excellent choice for components in heavy-duty machinery, automotive parts, aerospace applications, and other industries where the material will be exposed to high levels of mechanical stress over time.

Applications of Cold-Drawn Hexagonal Steel

Cold-drawn hexagonal steel is used in a variety of industries and applications due to its superior mechanical properties and precise dimensions.

Automotive Industry

In the automotive industry, cold-drawn hexagonal steel is used for components that require high strength, precision, and durability. It is commonly found in parts such as axles, suspension components, and shafts. Cold-drawn hexagonal steel's resistance to fatigue and wear ensures the longevity of these parts, which are exposed to significant stress during vehicle operation.

Aerospace Engineering

Aerospace applications require materials that can withstand extreme conditions while maintaining high strength-to-weight ratios. Cold-drawn hexagonal steel is used for structural components, brackets, pins, and other critical parts that require precise dimensions and high strength. The increased resistance to fatigue and wear ensures the durability of these components, even in the demanding environments of aerospace applications.

Construction and Structural Engineering

Cold-drawn hexagonal steel plays a key role in reinforcing structures and supporting heavy loads in construction and structural engineering. It is used for reinforcing bars (rebar), framework supports, and other structural components where strength and precision are critical for safety and stability. Cold-drawn hexagonal steel provides the necessary strength and durability for these applications, ensuring the integrity of the overall structure.

Machinery Manufacturing

In machinery manufacturing, cold-drawn hexagonal steel is often used to produce gears, pins, shafts, and other high-precision components. The high dimensional accuracy and superior surface finish make it ideal for components that require smooth operation and minimal friction. Cold-drawn hexagonal steel ensures reliable and durable parts for various types of machinery, from small equipment to large industrial systems.

Cost-Efficiency and Customization Options

Cost Benefits Over Other Steel Types

Cold-drawn hexagonal steel is often more cost-effective than other materials such as forged steel, while still providing superior performance and precision. Although the initial cost may be slightly higher than hot-rolled steel, the benefits of enhanced strength, precision, and durability often outweigh the additional cost in long-term applications.

For projects that require high-performance steel, cold-drawn hexagonal steel provides excellent value, as it reduces the need for additional machining or processing due to its tight tolerances and superior surface finish.

Customization of Size and Grade

Cold-drawn hexagonal steel can be customized to meet specific project requirements. Whether you need a particular diameter, length, or grade, cold-drawn hexagonal steel can be tailored to match your application’s needs.

Diameter and Length: Cold-drawn hexagonal steel is available in a range of sizes, from small diameters (e.g., 5mm) to larger ones (e.g., 100mm), and can be cut to specific lengths to fit your design.

Material Grade: Choose from a variety of material grades, such as Q195, Q235, 1045, or 42CrMo, depending on the strength and durability requirements of your application.

Working with Suppliers for Custom Orders

When placing custom orders, it is important to communicate your specifications clearly to ensure that you receive the right product. Reliable suppliers can work with you to tailor the steel to your exact needs, ensuring that it fits perfectly within your project.

Quality Assurance and Industry Standards

Quality Standards to Look For

To ensure the reliability and performance of your cold-drawn hexagonal steel, it is important to choose a supplier that adheres to recognized quality standards. Look for certifications such as ISO 9001, which demonstrates that the supplier maintains a high standard of quality control and manufacturing processes.

Verifying Product Quality

Before purchasing cold-drawn hexagonal steel, ask for material certificates and product specifications to verify the steel's quality. These documents will confirm that the material meets your required standards and will perform well in your application.

Conclusion

Cold-drawn hexagonal steel offers a variety of key benefits, including high dimensional precision, superior surface finish, increased strength, and resistance to wear and fatigue. These features make it the ideal choice for numerous industries such as automotive, aerospace, construction, and machinery manufacturing. By selecting cold-drawn hexagonal steel, you ensure that your project meets the highest standards of performance, durability, and cost-effectiveness.

At Tianjin Shengxiang Cold Drawn Steel Co., Ltd., we specialize in providing high-quality cold-drawn hexagonal steel tailored to meet your specific needs. Whether you require precise dimensions, superior strength, or customized sizes, our team is dedicated to offering solutions that enhance the efficiency and reliability of your manufacturing process.

We work closely with our clients to deliver products that fit the exact requirements of your project. Contact us today to explore how our cold-drawn hexagonal steel can help you achieve optimal results for your application.

FAQs

Q1: How does cold-drawn hexagonal steel differ from hot-rolled steel?

Cold-drawn hexagonal steel provides tighter dimensional tolerances, a smoother surface finish, and superior mechanical properties compared to hot-rolled steel, making it ideal for precision applications.

Q2: What are the common grades used for cold-drawn hexagonal steel?

Common grades include Q195, Q235, 1045, and 42CrMo, each offering different levels of strength and hardness for various applications.

Q3: Can cold-drawn hexagonal steel be customized for specific lengths and diameters?

Yes, cold-drawn hexagonal steel can be customized to meet specific project requirements, including custom diameters, lengths, and material grades.

Q4: What types of applications benefit most from using cold-drawn hexagonal steel?

Applications in automotive, aerospace, construction, and machinery manufacturing benefit from cold-drawn hexagonal steel due to its precision, strength, and durability.

Q5: What are the advantages of using cold-drawn hexagonal steel in high-stress applications?

Cold-drawn hexagonal steel provides superior resistance to fatigue, wear, and stress, making it ideal for applications that require high strength and durability.