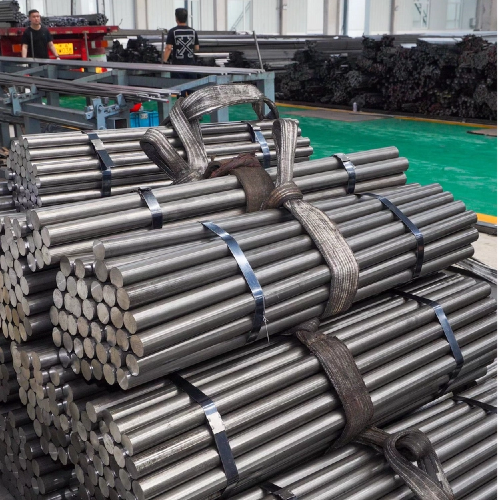

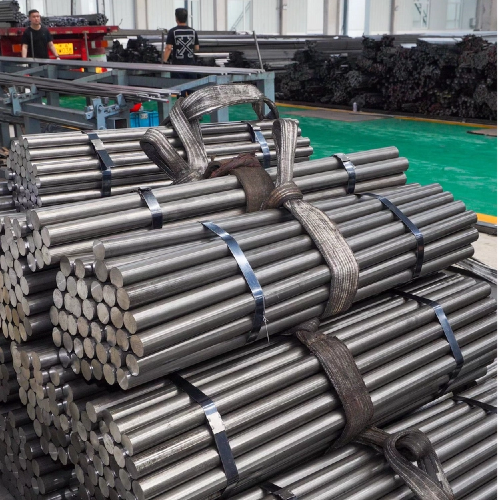

Cold drawn round steel is a highly versatile material used in various industries, providing key advantages in terms of precision, strength, and durability. It undergoes a cold drawing process, which imparts significant improvements over other types of steel, particularly in terms of mechanical properties and surface finish. This article will explore the key properties of cold drawn round steel, its applications, advantages, and how to choose the right type for your project.

Introduction to Cold Drawn Round Steel

Cold drawn round steel is produced through a cold drawing process that stretches steel billets or bars through a die to produce a steel bar with precise dimensions. This process not only enhances the mechanical properties of the steel but also gives it a smooth, consistent surface that is ideal for precision applications. Cold drawn round steel is widely used in industries requiring high-strength, durable, and accurate steel materials.

In this article, we will discuss the key properties of cold drawn round steel, its applications across different industries, and why it is often the preferred material in precision engineering.

Key Properties of Cold Drawn Round Steel

High Dimensional Precision

One of the standout features of cold drawn round steel is its high dimensional precision. The cold drawing process allows for very tight tolerances, typically between 0.1 and 0.5mm. This level of precision is critical in applications where exact measurements are necessary, such as in shafts, bolts, and pins used in mechanical assemblies.

Property | Cold Drawn Round Steel | Hot Rolled Steel |

Tolerance | High precision, tight tolerances (0.1mm to 0.5mm) | Lower precision, wider tolerances |

Surface Finish | Smooth, uniform finish | Rougher surface finish |

Strength | Higher tensile strength and hardness | Lower strength |

The ability to achieve precise measurements makes cold drawn round steel ideal for industries such as automotive, aerospace, and precision machinery, where tight tolerances are required for safety and functionality.

Improved Surface Finish

Cold drawn round steel has a superior surface finish compared to hot rolled steel. The cold drawing process removes scale and surface imperfections, resulting in a smooth and clean surface that is free from oxidation. This is especially important for components that are highly visible or need to fit tightly with other parts.

The smooth surface finish also minimizes friction, making cold drawn round steel an excellent choice for components like gears, shafts, and structural parts that require smooth movement and interaction with other components.

Enhanced Strength and Toughness

The strength and toughness of cold drawn round steel are significantly improved through the cold drawing process. The process increases the material’s tensile strength and yield strength, making it stronger and more resistant to wear and tear compared to hot rolled steel. This makes cold drawn round steel ideal for high-stress applications, such as in heavy-duty machinery or structural components.

Cold drawing also refines the grain structure of the steel, which enhances its toughness, ensuring it can withstand impact and high stress without failing. This is particularly beneficial in industries like construction and automotive manufacturing, where durability is paramount.

Uniformity and Consistency

Cold drawn round steel offers uniformity and consistency across long lengths of steel. The process ensures that the steel’s mechanical properties, such as strength and hardness, are evenly distributed throughout the material. This uniformity is critical for applications where the steel will be used in multiple components, all of which must meet the same standards for performance.

The consistency of cold drawn round steel also makes it easier to machine, weld, and fabricate, as it behaves predictably during the manufacturing process. This predictability reduces the risk of defects and ensures high-quality finished products.

Applications of Cold Drawn Round Steel

Cold drawn round steel is used in a variety of industries, particularly in applications that require precision, strength, and durability. Some of the most common uses of cold drawn round steel include:

Automotive Industry

Cold drawn round steel is used extensively in the automotive industry for manufacturing components like axles, suspension parts, and shafts. The precision and strength of cold drawn round steel ensure that automotive parts can withstand high levels of stress and wear over time. Cold drawn round steel is also used in the production of bolts and fasteners, where tight tolerances and strength are crucial for vehicle safety.

Aerospace Industry

In aerospace, cold drawn round steel is used for producing critical components such as landing gear, wing structures, and engine parts. The high strength-to-weight ratio of cold drawn round steel makes it an ideal material for aircraft components that must endure extreme conditions while minimizing weight. The precision of the steel ensures that parts fit perfectly, which is vital for safety and performance in aerospace applications.

Construction and Structural Applications

Cold drawn round steel is frequently used in construction for making structural components such as beams, columns, and supports. The high tensile strength and dimensional accuracy of the steel make it suitable for high-load applications where safety and reliability are essential. Cold drawn round steel is also used for reinforcing bars (rebar) in concrete, ensuring the stability and integrity of buildings and infrastructure.

Machinery and Equipment Manufacturing

Machinery parts, including shafts, gears, and pins, require materials that are both strong and precise. Cold drawn round steel is an ideal choice for these applications due to its high tensile strength, toughness, and smooth surface finish. The uniformity of cold drawn round steel ensures that parts are durable and can operate smoothly under high-stress conditions.

Advantages of Cold Drawn Round Steel Over Other Steel Types

When compared to hot rolled or forged steel, cold drawn round steel offers several advantages in terms of strength, precision, and surface finish. The cold drawing process refines the material's microstructure, improving its mechanical properties and surface finish, making it ideal for precision applications.

Advantage | Cold Drawn Round Steel | Hot Rolled Steel | Forged Steel |

Dimensional Precision | Very high precision | Low precision | Moderate precision |

Surface Finish | Smooth and uniform | Rough, uneven | Smooth but with some imperfections |

Strength | Higher tensile and yield strength | Moderate strength | Very high strength |

Cost | Moderate to high | Lower | High |

For applications that require tight tolerances, a smooth surface, and superior mechanical properties, cold drawn round steel is often the preferred choice.

Choosing Cold Drawn Round Steel for Your Projects

When selecting cold drawn round steel for a project, several factors should be considered to ensure that the material meets the specific requirements of the application.

Factors to Consider:

Material Grade: Choose the appropriate grade based on the required strength, toughness, and resistance to corrosion.

Diameter and Length: Cold drawn round steel is available in a wide range of diameters and lengths, and customization options are often available.

Tolerance Requirements: Cold drawn round steel offers tight tolerances, making it ideal for projects that require high dimensional accuracy.

Surface Finish: Consider the level of surface finish required for your application, as cold drawn steel offers a smooth, uniform surface.

Customization and Order Options for Cold Drawn Round Steel

Many suppliers offer customization options for cold drawn round steel. These include variations in diameter, length, and material grade to suit the specific needs of the customer. Cold drawn round steel can also be cut to length or supplied in coils, depending on the project requirements.

For bulk orders, most suppliers provide the option to place an order based on precise specifications, ensuring that the material meets the exact requirements of your manufacturing process. Customization can help streamline production and ensure consistency across components.

Conclusion

Cold drawn round steel is a highly versatile material known for its exceptional properties, making it the ideal choice for a wide range of industries. With its high dimensional precision, superior surface finish, enhanced strength, and consistent quality, cold drawn round steel ensures reliability and performance in demanding applications. Whether you're involved in automotive manufacturing, aerospace engineering, or construction, this material provides the durability, strength, and accuracy required to meet your project needs.

At Tianjin Shengxiang Cold Drawn Steel Co., Ltd., we specialize in providing top-quality cold drawn round steel tailored to your specific requirements. Our products are designed to meet the highest standards, ensuring that they perform optimally in various industrial applications. We offer custom sizes, grades, and finishes to suit your project specifications. Contact us today to learn more about how our cold drawn round steel can enhance your manufacturing process, or to discuss how we can support your business needs with reliable and durable steel solutions.

FAQs

Q1: What is the difference between cold drawn and hot rolled steel?

Cold drawn steel is produced at room temperature, resulting in a smoother finish, higher precision, and stronger mechanical properties. Hot rolled steel, on the other hand, is produced at high temperatures, which results in lower dimensional accuracy and a rougher surface.

Q2: How does cold drawing improve the strength of round steel?

Cold drawing strengthens steel by refining its grain structure and increasing its tensile and yield strength. The cold working process helps to align the steel's molecules, making it tougher and more resistant to impact and wear.

Q3: Can cold drawn round steel be used in all industries?

Yes, cold drawn round steel is highly versatile and is used in industries such as automotive, aerospace, construction, and machinery manufacturing. Its strength and precision make it ideal for critical components in these sectors.

Q4: Is cold drawn round steel available in custom sizes and grades?

Yes, cold drawn round steel is available in various sizes and grades, and it can be customized to meet specific project requirements. Most suppliers offer flexibility in terms of diameters, lengths, and material grades.

Q5: What are the primary applications for cold drawn round steel?

Cold drawn round steel is used in applications such as shafts, gears, pins, bolts, and other precision components that require high strength and dimensional accuracy. It is commonly found in industries like automotive, aerospace, and construction.