Cold-drawn hexagonal steel is increasingly becoming the material of choice for unique design applications across various industries. Its high precision, superior surface finish, enhanced strength, and ability to be customized make it an ideal option for projects that require a combination of performance and flexibility. This article explores why cold-drawn hexagonal steel is so advantageous for unique design applications and how it supports innovative engineering solutions.

What Is Cold-Drawn Hexagonal Steel?

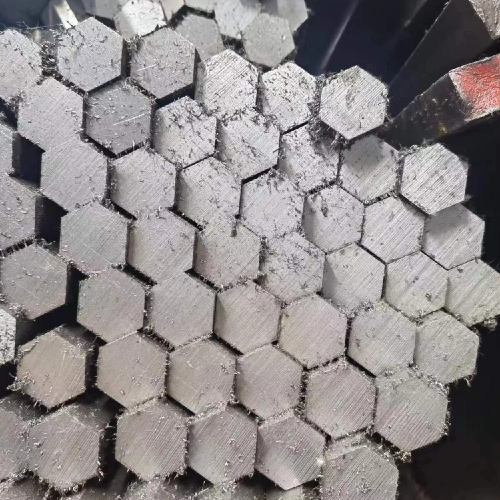

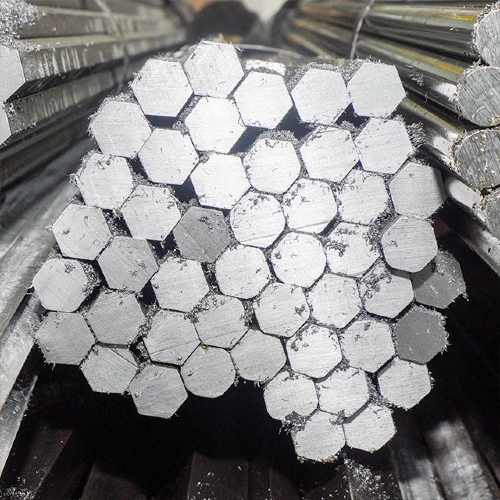

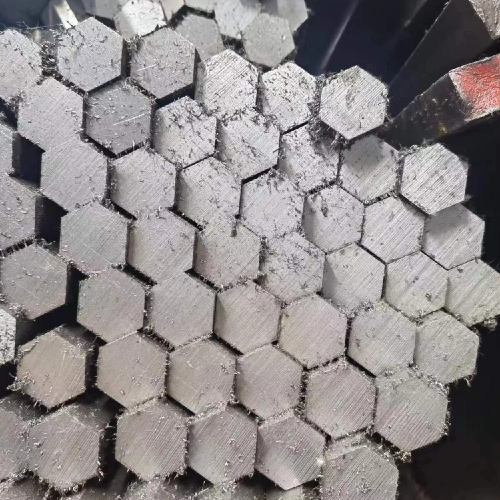

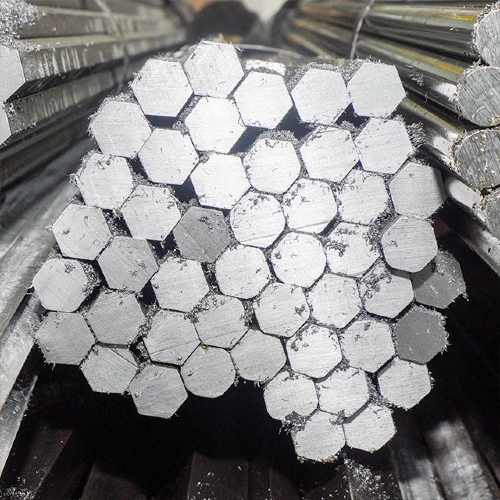

Cold-drawn hexagonal steel is produced by drawing a steel bar through a die at room temperature. This process alters the material's structure, making it stronger, more precise, and offering a smooth finish. Unlike hot-rolled steel, which can be imprecise and have a rougher surface, cold-drawn hexagonal steel is specifically designed to meet the demands of high-performance applications.

The cold-drawing process results in tight dimensional tolerances and a smooth, uniform surface, which is essential in various industrial sectors. The ability to manipulate the material to specific shapes and sizes while enhancing its mechanical properties is what makes cold-drawn hexagonal steel ideal for unique design applications.

Key Benefits of Using Cold-Drawn Hexagonal Steel for Unique Design Applications

High Dimensional Precision

One of the main reasons cold-drawn hexagonal steel is used in design applications is its high dimensional precision. The cold-drawing process allows for tight control over the steel’s dimensions, ensuring that it meets the exact specifications required for custom parts. Cold-drawn steel typically achieves tolerances of ±0.05mm to ±0.1mm, making it perfect for applications where precision is crucial.

This dimensional accuracy is particularly important in industries like automotive manufacturing, aerospace, and construction, where parts must fit together perfectly. Cold-drawn hexagonal steel’s precision reduces the need for additional machining, which can save time and costs during production.

Diameter Range | Tolerance | Applications |

< 10mm | ±0.05mm to ±0.1mm | Small parts, fasteners, pins |

10mm to 50mm | ±0.1mm to ±0.2mm | Shafts, structural components |

> 50mm | ±0.2mm to ±0.5mm | Heavy-duty applications |

Superior Surface Finish

Another significant benefit of cold-drawn hexagonal steel is its superior surface finish. The cold-drawing process helps to create a smooth, clean surface that is free from scale, rust, and other imperfections that can affect the performance and appearance of steel. This is especially important for parts that need to move smoothly within mechanical systems or have a visual aesthetic requirement.

The smooth surface finish also reduces friction and wear between moving parts, increasing the lifespan of the components made from cold-drawn hexagonal steel. This is an important consideration in the automotive, aerospace, and machinery industries, where components must operate efficiently and withstand constant movement.

Enhanced Strength and Durability

Cold-drawn hexagonal steel is known for its increased strength compared to hot-rolled steel. The cold-drawing process enhances the material's tensile strength and yield strength, making it more resistant to deformation and failure under high stress. This improved strength also increases the material's hardness, making it more resistant to wear, abrasion, and fatigue.

For design applications requiring components that must endure high levels of mechanical stress, cold-drawn hexagonal steel provides the durability needed. Whether it’s a custom part for automotive machinery or an aerospace component, cold-drawn hexagonal steel offers a robust solution for long-term performance.

Uniform Mechanical Properties

Cold-drawn hexagonal steel is engineered to have uniform mechanical properties throughout its length. The cold-drawing process aligns the material’s grain structure, which results in a consistent distribution of strength, toughness, and hardness. This uniformity is crucial in applications where the steel needs to perform predictably and consistently over time.

For instance, in mass production applications, where thousands of identical parts are required, the uniformity of cold-drawn hexagonal steel ensures that every part performs in the same manner. This reduces the likelihood of defects and ensures that all parts meet the same high standards of quality and performance.

Increased Resistance to Fatigue and Wear

Cold-drawn hexagonal steel also offers increased resistance to fatigue and wear. The refinement of the material’s microstructure during cold drawing makes it more resistant to repeated loading and abrasive wear. This is especially beneficial in industries like aerospace and automotive, where components are exposed to repetitive stress over long periods.

Parts made from cold-drawn hexagonal steel are more likely to withstand fatigue cycles without cracking or failing. This property makes it ideal for applications in high-stress environments, such as structural components, gears, and mechanical parts that operate under intense forces.

Applications of Cold-Drawn Hexagonal Steel in Unique Design Projects

Automotive and Aerospace Industries

Cold-drawn hexagonal steel is frequently used in the automotive and aerospace industries due to its strength, precision, and reliability. In the automotive sector, components such as axles, shafts, and brackets often require custom-made parts that can withstand high loads and harsh conditions. Cold-drawn hexagonal steel provides the necessary mechanical properties to ensure these parts are durable and reliable.

In aerospace engineering, where both strength and weight reduction are critical, cold-drawn hexagonal steel is used in the production of structural parts and fasteners. The material’s high strength-to-weight ratio makes it ideal for components that must perform under extreme conditions while keeping weight to a minimum.

Construction and Structural Engineering

Cold-drawn hexagonal steel plays a vital role in structural engineering, where custom steel components are often needed to support heavy loads and provide stability. Cold-drawn hexagonal steel is commonly used for reinforcing bars (rebar), framework supports, and other structural elements that require high tensile strength and durability.

The material’s ability to be customized in terms of size, strength, and surface finish makes it an ideal solution for unique construction projects that require specific specifications. It provides the strength and durability needed to ensure the safety and integrity of buildings, bridges, and other structures.

Machinery Manufacturing

In machinery manufacturing, cold-drawn hexagonal steel is used to produce gears, pins, shafts, and other high-precision components that require both durability and accuracy. The material’s high dimensional precision and uniform mechanical properties ensure that parts function smoothly and consistently.

Cold-drawn hexagonal steel is particularly useful in applications where parts need to interact with one another with minimal friction. Its superior surface finish and increased resistance to wear make it ideal for parts that are in constant motion or under heavy load, such as in industrial machines, vehicles, and other equipment.

How Cold-Drawn Hexagonal Steel Supports Innovative Design Ideas

Cold-drawn hexagonal steel allows designers and engineers to explore innovative design ideas that may not be possible with other materials. The material’s precision, strength, and versatility provide the flexibility needed to create custom shapes, complex geometries, and tailored designs for specific applications.

Example 1: Lightweight Structural Components

By using cold-drawn hexagonal steel, engineers can create lightweight yet strong structural components that don’t compromise on performance. This is particularly important in the aerospace and automotive industries, where weight reduction is essential for fuel efficiency and performance.

Example 2: Custom Parts for Machinery

In machinery manufacturing, cold-drawn hexagonal steel can be customized to fit complex designs that require specific dimensions and mechanical properties. Designers can create parts that fit seamlessly into existing systems, improving overall efficiency and performance.

Example 3: Unique Design Shapes

The cold-drawing process allows for the creation of custom cross-sections and unique shapes that may not be achievable with other forms of steel. This flexibility is particularly useful in applications where off-the-shelf components are not suitable, such as in specialized machinery or architectural features.

Cost-Effectiveness of Cold-Drawn Hexagonal Steel for Custom Designs

Cost Benefits Over Other Steel Types

While cold-drawn hexagonal steel may have a slightly higher upfront cost than hot-rolled steel, it offers long-term cost savings due to its precision and reduced need for additional machining. Because cold-drawn steel comes with tighter tolerances and a superior surface finish, there is less need for additional processing, which can save both time and money in the production process.

Additionally, the increased strength and durability of cold-drawn hexagonal steel mean that components made from this material are more likely to last longer, reducing maintenance and replacement costs over time.

Customization of Size and Grade

Cold-drawn hexagonal steel’s ability to be customized makes it an economical choice for bespoke applications. Customers can select the exact diameter, length, and grade required for their project, eliminating waste and ensuring that only the necessary amount of material is used.

Customizing cold-drawn hexagonal steel allows manufacturers to meet the specific needs of a project without overspending on excess material, making it a highly cost-effective choice for unique design applications.

Quality Assurance and Industry Standards

Quality Standards to Look For

When sourcing cold-drawn hexagonal steel, it is important to choose suppliers that adhere to industry-recognized quality standards. Look for certifications such as ISO 9001, which ensures that the supplier follows strict quality control and manufacturing processes. Suppliers should also provide material certificates to confirm the steel’s mechanical properties and suitability for the intended application.

Verifying Product Quality

To ensure that the cold-drawn hexagonal steel you purchase meets the required standards, always verify the product’s quality before use. Request certifications and detailed specifications from the supplier to confirm the material’s strength, hardness, and tolerance levels. A reliable supplier will provide these documents and work with you to meet your unique project needs.

Conclusion

Cold-drawn hexagonal steel offers numerous advantages for unique design applications, including high precision, superior surface finish, enhanced strength, and the ability to be customized for specific project needs. Its versatility and durability make it an ideal choice for industries such as automotive, aerospace, construction, and machinery manufacturing, where performance and precision are paramount.

At Tianjin Shengxiang Cold Drawn Steel Co., Ltd., we specialize in providing high-quality cold-drawn hexagonal steel tailored to meet the demands of your unique projects. Our products are designed to enhance the innovation, reliability, and performance of your designs. Whether you need precise dimensions, superior surface finish, or customized sizes, we offer solutions that support your engineering challenges.

Contact us today to learn more about how our cold-drawn hexagonal steel can contribute to the success of your next project. Our team is ready to assist you in selecting the best material to meet your specific requirements.

FAQs

Q1: How does cold-drawn hexagonal steel differ from hot-rolled steel?

Cold-drawn hexagonal steel offers tighter dimensional tolerances, a smoother surface finish, and improved strength compared to hot-rolled steel, making it ideal for precision applications.

Q2: What are the common grades used for cold-drawn hexagonal steel?

Common grades include Q195, Q235, 1045, and 42CrMo, each offering different strengths and hardness levels for various applications.

Q3: Can cold-drawn hexagonal steel be customized for specific design requirements?

Yes, cold-drawn hexagonal steel can be tailored in terms of size, material grade, and surface finish to meet the exact needs of your project.

Q4: What types of applications benefit most from using cold-drawn hexagonal steel?

Industries such as automotive, aerospace, construction, and machinery manufacturing benefit from cold-drawn hexagonal steel due to its precision, strength, and durability.

Q5: Is cold-drawn hexagonal steel cost-effective for custom design projects?

Despite its slightly higher initial cost, cold-drawn hexagonal steel can offer long-term cost savings by reducing the need for additional machining, improving part longevity, and ensuring high performance.