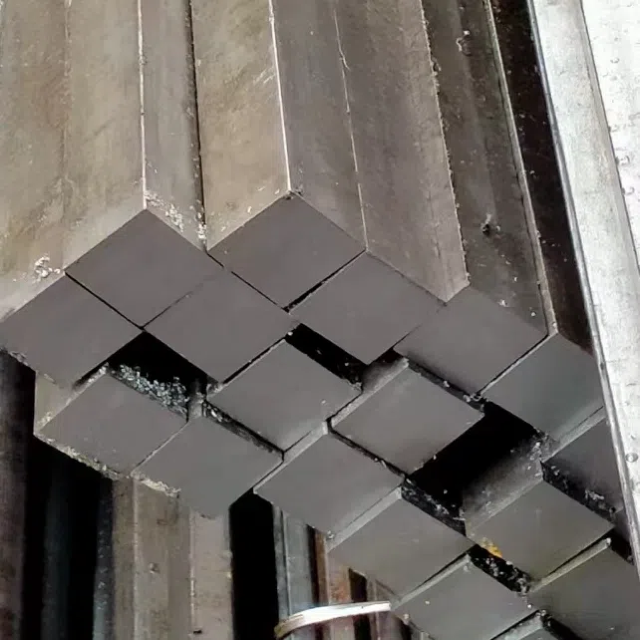

In the fast-paced world of manufacturing, the demand for materials that combine strength, precision, and cost-effectiveness is ever-increasing. At Tianjin Shengxiang Cold Drawn Co., Ltd., we take pride in offering high-quality cold drawn steel bars that meet the exacting standards of industries worldwide. Our cold drawn steel bars undergo a meticulous manufacturing process that ensures superior strength, durability, and precision, making them a top choice for manufacturers in sectors such as automotive, heavy machinery, and more. By understanding the challenges faced by modern industries, we offer a solution that not only meets but exceeds expectations, helping manufacturers produce top-tier products with reduced costs and increased efficiency.

Benefits for Manufacturing: Strength and Durability

Cold drawn steel bars are known for their exceptional strength and mechanical properties, offering superior performance compared to hot-rolled alternatives. The cold drawing process involves pulling steel through a die at room temperature, which refines its microstructure and increases its strength. This process results in a material with enhanced tensile strength, resistance to deformation, and improved surface finish, making it ideal for applications where precision and durability are crucial.

Unlike hot-rolled steel, which can have variations in size and shape, cold drawn steel bars are produced to highly consistent dimensions. This level of precision reduces the need for additional machining processes, saving both time and money in production. The strength and uniformity of cold drawn steel make it an excellent choice for applications that require high-performance materials, especially in industries with demanding requirements.

Cold drawn steel’s ability to maintain its structural integrity under extreme conditions is a key reason it is preferred for critical applications. Whether it is subjected to high temperatures, heavy loads, or continuous stress, cold drawn steel retains its shape and mechanical properties, ensuring long-lasting performance. This quality contributes to the overall safety and reliability of end products, particularly in industries like automotive and heavy machinery, where failure is not an option.

Cold Drawn Steel Bars in Automotive Manufacturing

At Tianjin Shengxiang Cold Drawn Co., Ltd., we understand the critical role that cold drawn steel plays in the automotive industry. Automotive manufacturers rely on our cold drawn steel bars to produce safety-critical components, including axles, shafts, and connecting rods. These parts must withstand harsh operating conditions and meet stringent safety standards, which is why the strength and precision of cold drawn steel are so essential.

Our cold drawn steel bars provide exceptional fatigue resistance, making them ideal for components subjected to repetitive stress. This durability ensures that parts perform reliably under extreme conditions, from high temperatures to intense pressure. The precision of our cold drawn steel also minimizes the need for additional machining, reducing production costs and ensuring that automotive components are made to exact specifications.

The automotive sector requires parts that not only function efficiently but also meet regulatory and safety standards. Cold drawn steel’s superior mechanical properties make it the material of choice for manufacturers looking to produce high-performance parts with minimal risk of failure. By choosing our cold drawn steel, automotive manufacturers gain the peace of mind that their components will meet the toughest standards for safety and durability, while also benefiting from cost savings in the manufacturing process.

Cold Drawn Steel in Heavy Machinery Manufacturing

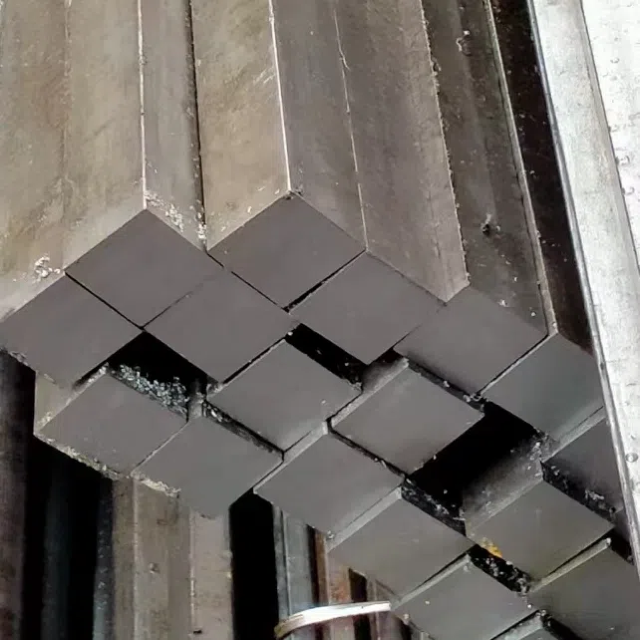

The importance of cold drawn steel in the heavy machinery sector cannot be overstated. Components such as gears, shafts, and hydraulic parts must be strong enough to endure heavy loads and extreme operating conditions. At Tianjin Shengxiang Cold Drawn Co., Ltd., our cold drawn steel bars are the material of choice for manufacturers of heavy machinery, offering exceptional strength and toughness.

Cold drawn steel bars used in heavy machinery are designed to withstand high pressure, impact, and wear. Their resistance to deformation under stress ensures that machinery can operate efficiently with minimal maintenance. Additionally, the smooth surface finish of our cold drawn steel reduces friction, contributing to the longevity of the components and reducing wear on moving parts. This enhances the overall performance and reliability of the machinery, helping businesses keep their operations running smoothly.

In the heavy machinery industry, downtime due to equipment failure is costly. That’s why durability is paramount, and cold drawn steel’s ability to resist wear, tear, and deformation ensures that components perform reliably over time. With cold drawn steel, machinery manufacturers can deliver products that require less maintenance, operate longer, and provide greater value to their customers.

Furthermore, cold drawn steel’s excellent machinability allows for precise fabrication of complex components with tighter tolerances, which is crucial in the production of high-performance heavy machinery. This high level of precision helps ensure that all parts fit together seamlessly, enhancing the overall functionality and efficiency of the machinery.

Cost-Effectiveness and Efficiency

One of the key advantages of cold drawn steel bars is their cost-effectiveness. At Tianjin Shengxiang Cold Drawn Co., Ltd., we produce cold drawn steel bars with precision and efficiency, ensuring that our customers receive high-quality materials at competitive prices. The cold drawing process reduces material waste and minimizes the need for additional machining, which helps to lower production costs.

Moreover, the durability and precision of cold drawn steel reduce the need for frequent maintenance and replacements. This long-lasting material provides cost savings over time, as products made from cold drawn steel require fewer repairs and replacements. By choosing our cold drawn steel bars, manufacturers can improve their bottom line while ensuring that their products maintain the highest standards of quality.

Cold drawn steel’s strength and dimensional accuracy also help manufacturers reduce the amount of scrap material in production, which is a common issue when using less precise materials. This increases yield and optimizes the overall manufacturing process, making it more cost-effective in the long term. With Tianjin Shengxiang Cold Drawn Co., Ltd., companies can maximize the use of raw materials while minimizing waste and inefficiencies.

The Role of Cold Drawn Steel in Modern Production Lines

In today’s automated and precision-driven manufacturing environments, cold drawn steel bars are indispensable. Tianjin Shengxiang Cold Drawn Co., Ltd. recognizes the importance of integrating precision materials into modern production lines, where automation and high-speed production are essential. Cold drawn steel’s uniformity and tight dimensional tolerances make it ideal for industries that rely on automated processes to produce high volumes of parts.

With automation increasingly driving manufacturing efficiency, the consistent dimensions and superior surface finish of cold drawn steel ensure seamless integration into production lines. This reduces the risk of errors and delays, helping manufacturers meet tight deadlines and improve production throughput. From medical devices to electronics, our cold drawn steel bars are the perfect solution for manufacturers seeking high-quality materials that enhance both productivity and product quality.

In addition, the increased use of robotics and automated machinery in production lines has highlighted the need for materials that can perform at high speeds without compromising on precision. Cold drawn steel’s exceptional dimensional accuracy makes it perfectly suited for high-speed automated processes, allowing manufacturers to produce large quantities of parts with minimal waste and maximum efficiency.

Conclusion

At Tianjin Shengxiang Cold Drawn Co., Ltd., we are committed to providing the highest-quality cold drawn steel bars to meet the needs of modern manufacturing. Our products are designed to offer superior strength, precision, and cost-effectiveness, making them the material of choice for industries ranging from automotive to heavy machinery. By choosing Tianjin Shengxiang Cold Drawn Co., Ltd., manufacturers can rely on our cold drawn steel bars to enhance the performance and longevity of their products, reduce production costs, and ensure the highest standards of quality.

As manufacturing continues to evolve with automation and precision engineering, the role of cold drawn steel bars will continue to grow. With our commitment to excellence and innovation, Tianjin Shengxiang Cold Drawn Co., Ltd. is proud to be at the forefront of this revolution, providing our customers with materials that meet the demands of today’s fast-paced manufacturing world. By choosing us as your partner, you ensure that your production lines are equipped with the best materials available, leading to higher efficiency, lower costs, and better products.